Wind power bearing ~ offshore wind power business opportunity!!!

In the production of Chuanchuan wind power. Bearings play a pivotal role. Because wind turbines are installed at high altitudes. Maintenance costs are high. At the same time, the working conditions are relatively harsh. They are vulnerable to pollution such as sand, dust, water mist, freezing and other pollution. It is required that the supporting bearings need to have high rigidity and high reliability to meet the requirements of its 20-year service life.

"Whether the wind turbine is good? Bearings are the core key element"

Wind power bearing is a special kind of bearing, which has harsh environment, high maintenance cost and long service life.

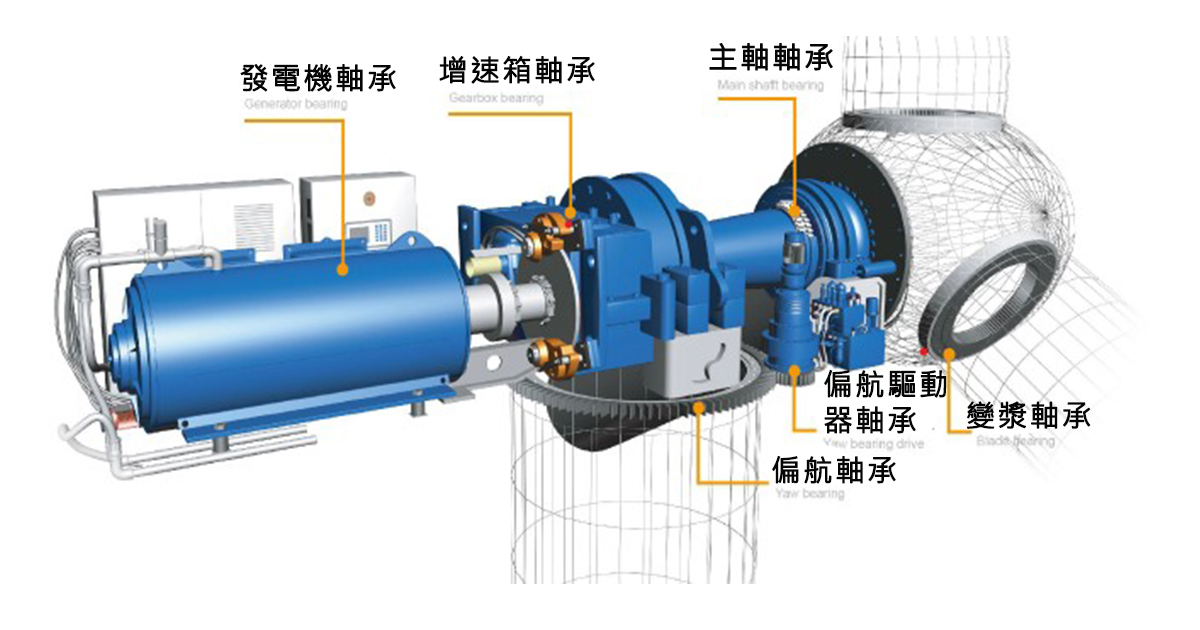

As a renewable, green and environmentally friendly new clean energy, wind power has been highly valued by all countries and has achieved considerable development. Bearings for wind turbines mainly include: yaw bearing assembly, blade main shaft bearing, transmission bearing, generator bearing, etc. The structure of the bearing mainly includes four-point contact ball bearings, cross roller bearings, cylindrical roller bearings, and self-aligning Roller bearings, deep groove ball bearings, etc. Among them, the large-scale yaw bearing assembly and the fan blade main shaft bearing are technically difficult. Now they basically rely on imports, which is one of the difficulties in the localization of wind turbines. The localization of wind turbine bearings can improve the design and application level of the domestic bearing industry, narrow the gap with the advanced level of foreign countries, and promote the development and technological progress of the domestic bearing industry. On the other hand, it can reduce the cost of wind power and accelerate my country's new energy and renewable energy. development of. Wind power bearing is a special kind of bearing, which has harsh environment, high maintenance cost and long service life.

Wind turbines work in the field all year round, the working conditions are relatively harsh, the temperature, humidity and bearing load change greatly, the wind speed can reach up to 23m/s, and there is impact load, so the bearing is required to have good sealing performance, lubrication performance, and impact resistance , Long life and high reliability, the generator must start when the wind is level 2~3, and can track the change of wind direction, so the bearing structure needs to be specially designed to ensure low friction and high sensitivity. Large yaw bearings require outer ring tooth. In order to better achieve the best condition of the wind turbine, the bearing design, material, manufacturing, lubrication and sealing must be specially designed to provide a stronger guarantee for the good operation of wind power equipment, which can greatly improve the performance and performance of the equipment. reliability.

Maintenance is also important in the wind power equipment system. Wind turbines are usually located in places that are not easy to maintain. They are often installed on mountains, in the desert or on the coastline. Condition monitoring systems can assist in monitoring the performance of the transmission system, and predictable maintenance can improve the performance and reliability of these systems and increase the effective operating time of the equipment. Such as monitoring equipment status through vibration analysis, oil analysis and infrared thermal imaging to determine the maintenance process at the best time for maintenance; predictive maintenance methods can improve the reliability of equipment operation, and only when the equipment needs maintenance Maintenance, reduce excessive maintenance and reduce maintenance costs.

Spindle bearing

Located at the main shaft of the impeller, the work load is high and the deformation of the main shaft is required to be compensated. Therefore, the bearing should have good alignment performance, high load capacity, and long service life. Generally, spherical roller bearings with optimized design are used.

Yaw bearing

The yaw mechanism installed in the base assembly of the nacelle of the wind turbine is used to accurately and timely adjust the windward angle of the wind turbine and conduct lightning to the ground. The load is: radial load, axial load and overturning moment. It is required to have good sealing performance, high reliability, flexible operation and good stability, surface corrosion, and a life span of more than 20 years. This type of bearing generally adopts super large four-point contact ball or crossed cylindrical roller slewing bearing.

Pitch bearing

The pitch system assembly located on the blade is used to adjust the windward direction of the blade, and it mainly bears radial load, axial load and overturning moment. The bearing is required to have good sealing performance, high reliability, surface corrosion, flexible operation, and a life span of more than 20 years. This type of bearing generally adopts extra-large four-point contact ball or double-row ball slewing bearing.

The green and clean energy of wind turbine bearings requires the support of the most advanced products. LDB closely follows the development trend of wind power generation and is committed to the development and manufacturing of bearings for wind turbines. It has formed the research and development of yaw bearings, blade (pitch) bearings, spindle bearings, and gearbox bearings for 600KW-2.0MW units. With manufacturing capacity, we can provide customers with series bearings for wind turbines. Key supporting bearings for wind turbines, including: yaw system bearings, pitch system bearings, transmission system bearings (main shaft and gearbox bearings), other system bearings (generator bearings and gear bearings), yaw system bearings: installed on the base of the wind turbine nacelle The formed yaw mechanism is used to accurately and timely adjust the windward angle of the wind turbine, and transmit lightning to the ground, carrying the full weight of the wind turbine's main drive system (radial load, axial load and overturning moment). It is required to have good sealing performance, high reliability, flexible operation and good stability, and surface anti-corrosion life of more than 20 years. This type of bearing generally uses super large four-point contact or crossed cylindrical roller slewing bearing. Pitch system bearing: The pitch system assembly located on the blade is used to adjust the windward direction of the blade, and it mainly bears radial load, axial load and overturning moment. The bearing is required to have good sealing performance, high reliability, surface corrosion, flexible operation, and a life span of more than 20 years. This type of bearing generally adopts four-fin contact or double-row ball extra-large slewing bearing. Main shaft bearing: Located on the main shaft of the fan blade, the work load is high and it is required to be able to compensate the deformation of the main shaft. Therefore, the bearing should have good alignment performance, high load capacity, and long service life. Generally, spherical roller bearings with optimized design are used. Wind power bearings, single-row cylindrical roller bearings, tapered roller bearings, insulated deep groove ball bearings, and locomotive axle box bearings used in subways and light rails, because the current and future development direction of the bushing is precisely around this * * Special technology for product development and manufacturing. Tanneng International Trade Co., Ltd.-Luoyang LYC electric bearing has the advantages of long life, corrosion resistance, can withstand the combined action of axial load, radial load and overturning moment; and single row cylindrical roller bearings, tapered roller bearings, and insulated deep grooves Ball bearings and other bearings used in subways and light rails can run at speeds of up to 100 kilometers per hour and have a life of 700,000 kilometers; as for locomotive axle box bearings, they have the characteristics of low friction, low vibration, high cleanliness and high precision. It has begun to develop towards lightweight, and can meet the operating speed of 160 kilometers per hour, up to 240 kilometers per hour.